Why Load Safety Matters

Every day, thousands of tons of goods are transported by road, rail and sea. Yet studies from European road safety agencies estimate that up to 20–25% of accidents involving heavy vehicles are linked to improperly secured cargo. Shifting loads can cause severe damage, injuries or fatalities, as well as costly fines and reputational loss for businesses.

Under European law, the driver, the shipper and the carrier are all responsible for safe load securing. Compliance is not only a legal obligation but also a fundamental part of corporate safety culture.

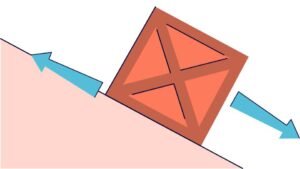

Understanding Friction and the Forces in Play

When a vehicle brakes, accelerates or corners, dynamic forces act on the cargo. These forces can reach up to 0.8 g forward, 0.5 g sideways, and 0.5 g backward, depending on the situation. If the friction between the load and the loading surface is too low, the cargo can slide despite lashing straps.

Friction is expressed as a coefficient (µ) and determines how much resistance exists between two surfaces. According to widely recognized European guidelines (e.g., VDI 2700), a minimum friction coefficient of 0.6 µ is often considered necessary for secure transport. Without measures to increase friction, most standard loading surfaces and cargo offer lower values.

For more details on legal standards and responsibilities, see our Regulations & Compliance page.

How Anti-Slip Mats Improve Safety

Anti-slip mats made from high-density recycled rubber are placed under pallets, steel coils or other loads to significantly increase friction. By boosting µ values, they stabilize the cargo and reduce the number of lashing straps required to meet safety standards. This saves time, protects goods, and minimizes risks for drivers and companies.

Certified mats are tested for friction performance, compressive strength, and durability. When used correctly and inspected regularly, they are reusable and withstand harsh weather and vibrations during transit.

Best Practices for Load Securing

Even with anti-slip mats, proper securing involves multiple factors:

- Keep loading surfaces and mats clean and dry; oil, dust and ice reduce friction.

- Distribute the load evenly to avoid tipping forces.

- Combine mats with proper lashing equipment, blocking and bracing.

- Replace mats if excessively worn, torn or contaminated.

For in-depth guidance on correct application methods and maintenance, see our Usage & Best Practices page.

Key Facts Box

Here are some key figures that highlight the importance of friction and proper load securing:

≥ 0.6 µ: Minimum friction coefficient recommended (VDI 2700)

0.8 g: Possible forward acceleration during braking

20–25%: Accidents due to improper load securing (EU data)

Reusability: Mats can be used multiple times with proper care

Learn More

For further reading from institutional sources:

- European Commission – Road Safety

- UNECE – Transport of Cargo Guidelines

- ISO Standards for Load Securing

Disclaimer

The information on this page is for general guidance only and should always be checked and adapted to each specific situation and applicable rules.

Although compiled with care, no guarantee is given for completeness or suitability.